Fabrication Designs

From laser-aligned layouts to custom-built systems, we deliver precision planning, BIM modeling, and prefabricated solutions that accelerate project timelines without compromising on quality or performance.

Design-Build / Design-Assist

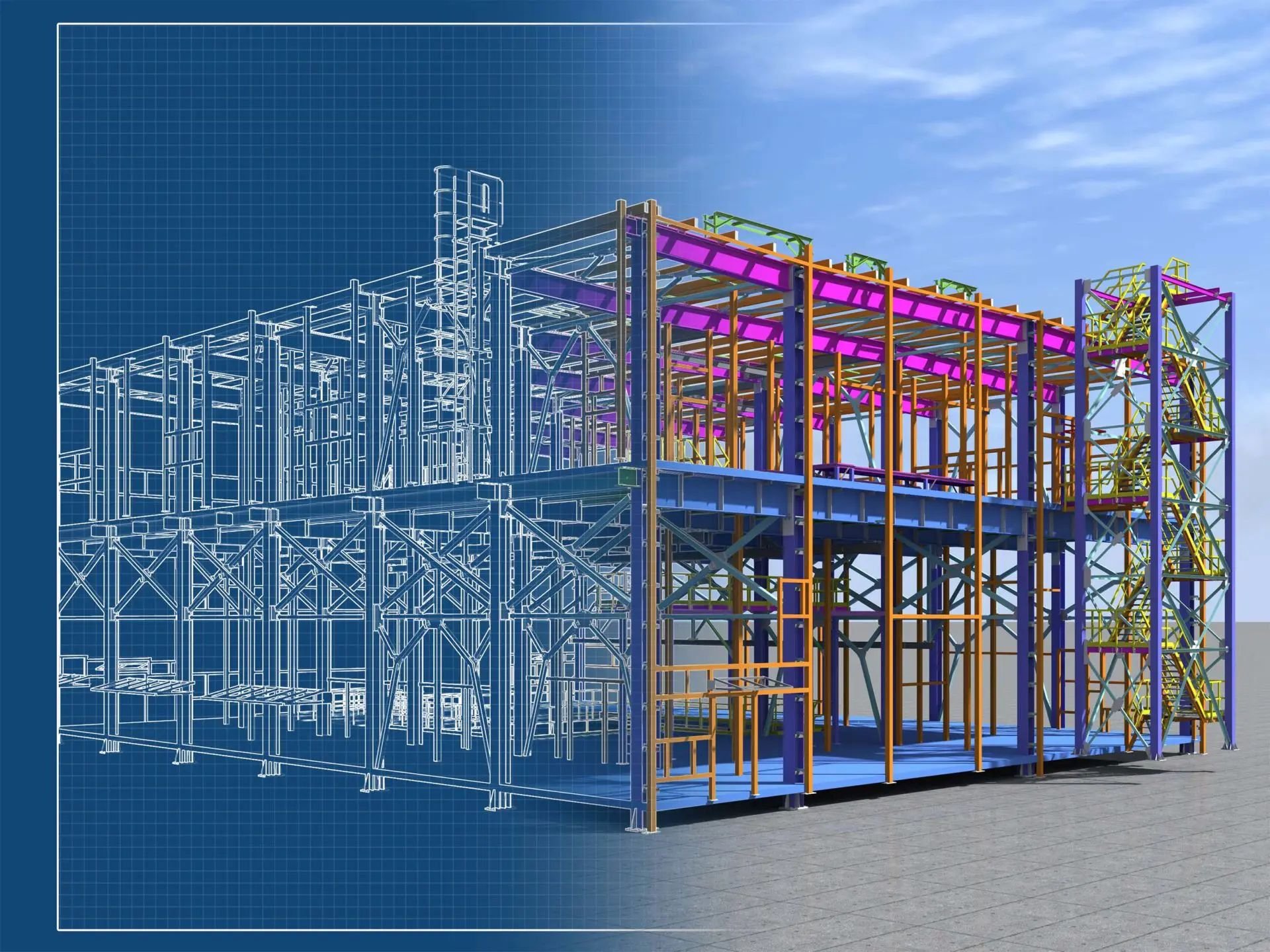

Full BIM / 3D AutoCAD Capabilities

Lean Construction Implementation

Precision Alignment of Complex Rotating Equipment

Trimble Mapping and GIS

Custom Piping System Fabrication

Equipment and Pump Skid Installation

Modular Component Installations

Off-site Prefabrication

Pipe Spools and Supports

Platforms, Stairways, Catwalks, and Handrails

Process Skid Fabrication

Rack-Mounted Process Piping

Custom-Built Systems Designed for Optimal Performance

Custom pipe spools and engineered support systems

Structural modular framing and pre-fabricated assemblies

Rack-mounted process piping solutions

Stuff boxes, chutes, and hoppers for material handling

Access components: stairways, catwalks, platforms, and handrails

Skid-mounted modules and manifold assemblies

Precision fittings: reducers, miters, elbows, tees, laterals, and wyes

Drainage solutions: save-alls, pans, floor boxes, and trench liner

Building Information Modeling (BIM)

Using advanced tools like Building Information Modeling (BIM), we coordinate seamlessly across disciplines to ensure systems fit and function as intended, reducing delays, preventing costly rework, and improving project outcomes. Our in-house fabrication capabilities enable us to produce a wide range of products, including pipe spools, structural framing, skid-mounted assemblies, and access components.

At Cochran Mechanical, we pride ourselves on delivering reliable, efficient solutions tailored to your specific application, built to last, and built with purpose.

At its core, BIM Coordination is about collaboration and clash detection. It helps identify conflicts—like a duct running through a beam—early in the design phase, so they can be resolved digitally rather than on-site, saving time, money, and rework.

Key Benefits:

Reduces costly on-site errors

Improves communication across teams

Streamlines scheduling and sequencing

Enhances constructability and project outcomes

Typical Workflow:

Model Aggregation – Combine models from all trades into a shared environment.

Clash Detection – Use software (like Navisworks or Revizto) to identify conflicts.

Issue Resolution – Coordinate with teams to resolve clashes and update models.

Model Sign-off – Finalize coordinated models for construction.